Regular PCB factory VS professional sample company, which one is better for proofing

PCB proofing refers to the production of a small number of PCB templates for functional debugging before the start of mass production of PCB; After the function debugging is completed, the subsequent batch production can be carried out, which can avoid the production risk and reduce the loss caused by product errors.

PCB proofing is divided into two ways, namely, regular PCB factory proofing. So, what are the differences between the two proofing? Now, let me tell you.

1. The purpose of regular PCB factory proofing is to have batch orders, and customers are expected to have returns; It only makes samples or small batches, and generally cannot make large orders.

2. In terms of quality assurance, regular PCB factories must do better than that. Usually, you will receive money when the sample is delivered, and you will not even make the basic flying needle. If there is a quality problem, you will not be responsible for returning or replacing the product; Regular PCB factories generally make flying needles, which are meticulous and professional from material to process, so PCB quality is guaranteed and there is perfect after-sales service.

3. Generally, for a project, the designed PCB drawings will be taken to a professional sample factory for proofing. First, a small number of PCB boards will be made. If they pass, they will find a regular PCB sample factory for direct mass production. The price will be much lower than that of a professional sample factory; The sample factory mainly focuses on rapid proofing.

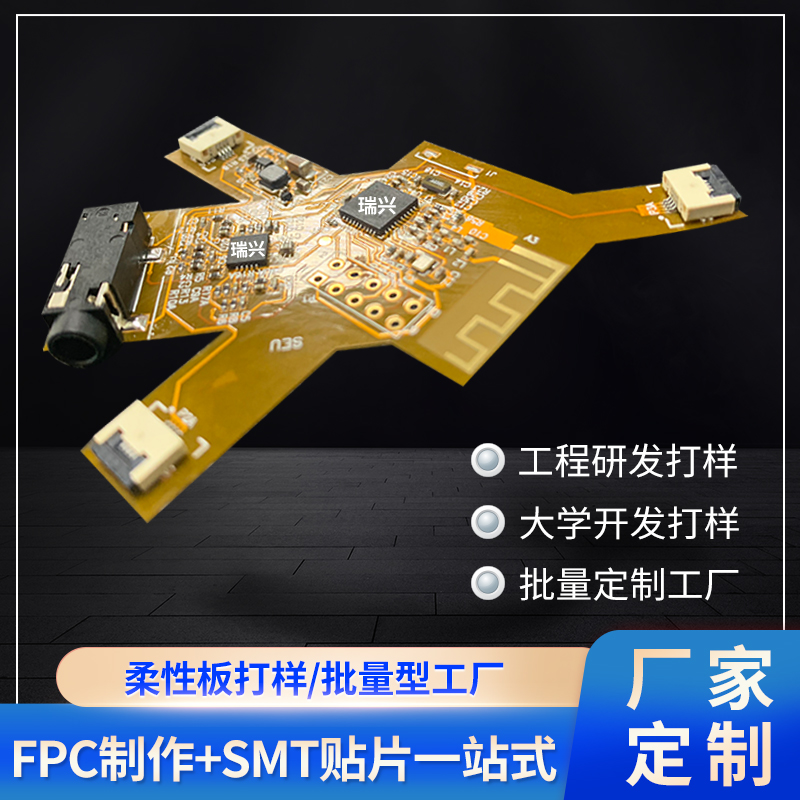

Ruixing Quick focuses on the technical innovation and user experience of PCB proofing, and has a team of product design engineers with rich experience in high-speed, high-frequency, high-power, analog, digital analog mixing, HDI and other fields. At this stage, we can also do various special processes that others do not want to do or rarely do according to customer needs, such as Rogers, HDI blind hole, impedance control, single and double aluminum substrates, single and double copper substrates, FPC, rigid flex bonding, thick copper plates, shaped holes, multi-layer special laminated structures, deep control grooves, nickel gold/gold finger electroplating, etc., to solve the pain points that enterprises have nowhere to process difficult plates, precision plates, and special plates in PCB proofing, To provide customers with high-quality and diversified PCB proofing services.